MINE GEOREFERENCING SERVICES

Scan On Demand

Here’s how it works:

- We ship the necessary hardware to your site

- You complete a scan of your mine

- When you’re finished, you ship the equipment back and either process the data yourself or allow us to do it for you

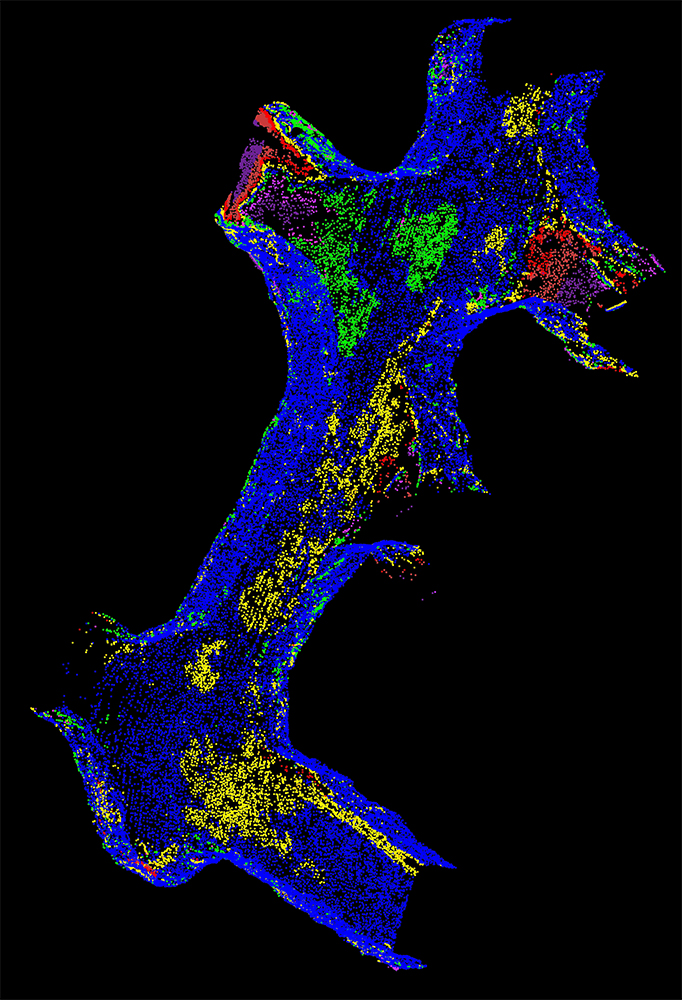

Convergence Monitoring

Utilizing fast and accurate scanning systems, MVS Convergence Monitoring will help you understand the geotechnical complexities and challenges of your mine, providing actionable insights for declines, ore drives/drifts, and stopes.

- Identify and interact with geotechnical changes over time

- Reduce costs through early identification of failing roof supports

- Avoid site downtime due to unknown movement

- Improved site safety

- Data results can be imported into mine planning software for further analysis and planning

- No interruption to operations or production during data collection

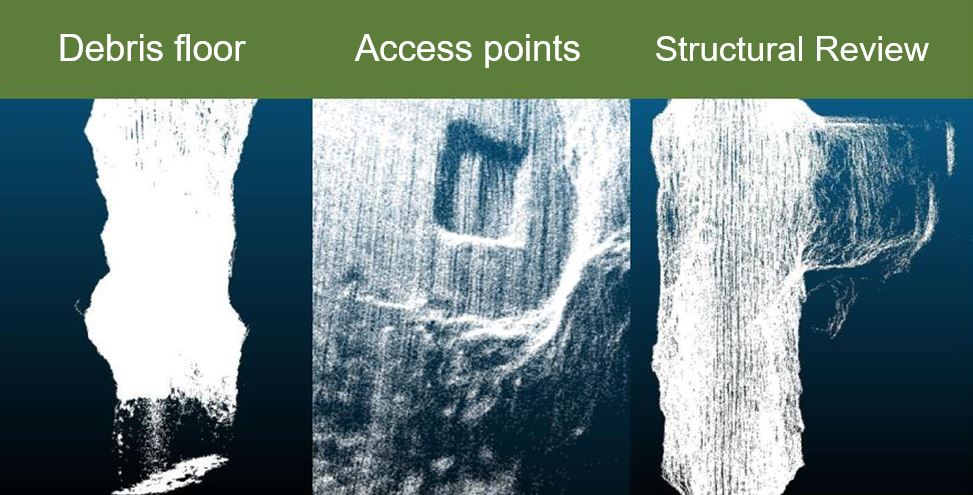

Mine Shaft Inspection

The MVS Shaft Inspection System provides a safe, cost effective method to inspect all types of shafts. Our system allows users to locate structural issues, measure change, monitor debris buildup, and assess and diagnose ventilation problems.

- Safely inspect shafts

- Easy to set up and deploy

- 3D data compatible with mine planning, CAD and 3D point cloud software

- Deliverable formats: ASC point clouds, OBJ textured mesh; Compatible with Leapfrog, AutoCAD, Geovia Surpac & other point cloud software

Mining Autonomy

The mining industry is seeing unprecedented demand for automating outdated and inefficient processes. Companies are recognizing the value of automation expertise in helping to drive down costs and increase production.

Mine Vision Systems is at the forefront of the mining automation space and helps clients see an increased level of efficiency, safety and productivity utilizing automated processes.

Taking an autonomy-based approach will:

- Increase Productivity

- Improve Safety

- Yield more accurate information

- Result in smarter, quicker decisions

- Boost confidence in your data and decision making